ENRESS 1000

Energy potential of the output products of thermal depolymerisation of waste tyres

Partners and collaborating institutions:

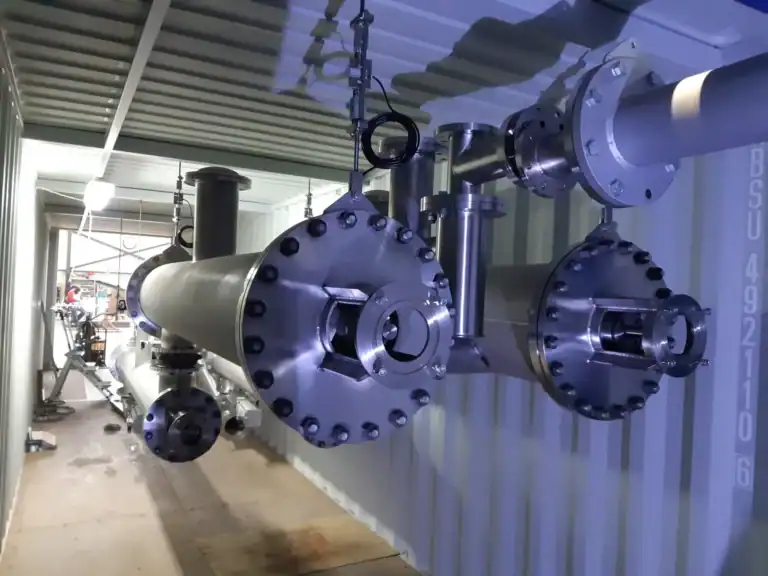

ENRESS 1000 - tyre disposal

How it works

The ENRRESS 1000 technology is designed to process 1,000 kg/hr of waste tyre crumb with 8,000 operating hours per year.

With the average material balance shown, the production of the individual fractions obtained is as follows:

| Mass fraction | Volume fraction | Calorific value | |

|---|---|---|---|

| A) Process gas | 230 kg/hr. | 221 m³/hr. | 31,8 MJ/m³ |

| B) liquid recyclate (oil) | 360 kg/hr. | 450 litres/hr. | 39 MJ/kg |

| (C) inert residue (residue) | 410 kg/hr (of which 70 kg/hr of metals) |

Use of process gas

The calorific value of the process gas reaches 31.8 MJ/m3 and thus enables an energy production potential of 1,952 kW/hr.

As always, it is advantageous to use process gas as a valuable and clean fuel for power generation. The operation of the ENRESS 1000 can be completely independent of a permanent connection to an external power source and can therefore be energy self-sufficient. The operating consumption of the technology is 380 kWh.

An energy unit with a standard electrical efficiency of 40% can produce the following from the energy potential of the recovered process gas 0.75 MW/hour of electricity and the same amount of usable heat.

Utilisation of liquid recyclate - oil

The calorific value of the liquid recyclate (oil) reaches 39 MJ/kg and allows an energy potential of 3.899 kW/hr.

Process oil can be used as a saleable commodity, e.g. as a liquid thermochemical recyclate for further processing in the chemical industry, or as a fuel for some types of diesel CHP units with the following options:

| production efficiency Ee | 36 % |

| Ee production | 1 400 kW/hr. |

| usable thermal energy | 056 kW (800 kW) |

The operating consumption of the technology is 380 kWh.

The use of inert carbon residue is possible in various industrial sectors

The ENRESS 1000 is supplied in a modular container solution with a size of 24.4 x 4.9 x 5.4 metres d x w x h and a total weight of approx. 24 tonnes.

The prerequisite for thermochemical recycling are tyres shredded to a size of 55×55 mm. For this purpose, we also supply shredding equipment in cooperation with partners.

Gallery