We create low-emission products from plastics

An environmentally friendly alternative to incineration and landfill that converts waste into energy and raw materials.

Partners and collaborating institutions:

Our STORY

About us

Founded in 2013, ENRESS specializes in the development, production and service of technologies for the environmentally friendly disposal and thermochemical recycling of waste plastics and other synthetic organic materials.

Innovative recycling

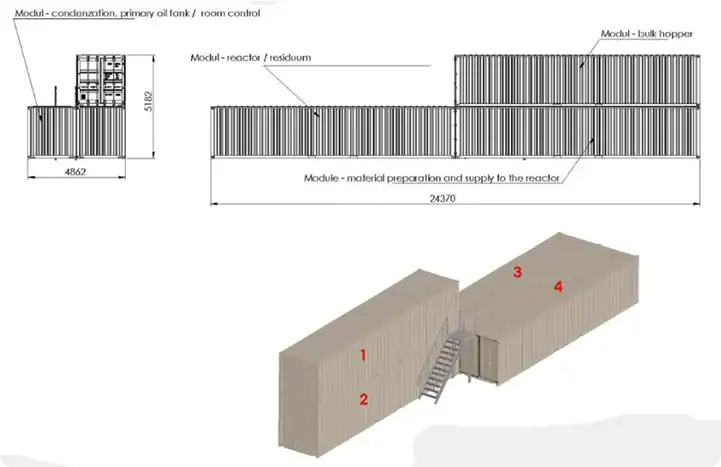

For the disposal of waste, its material recycling, the use of gaseous and in some cases also liquid output for the production of electricity, heat, cold or as an additive to fuel, we are ready to supply the TDU2000 technology in facilities with an annual input capacity of 5,600 and 8,000 tonnes of processed plastic or rubber waste respectively. However, the aim is to produce the majority of liquid recyclate for further use in existing petrochemical plants.

Oil as a new resource

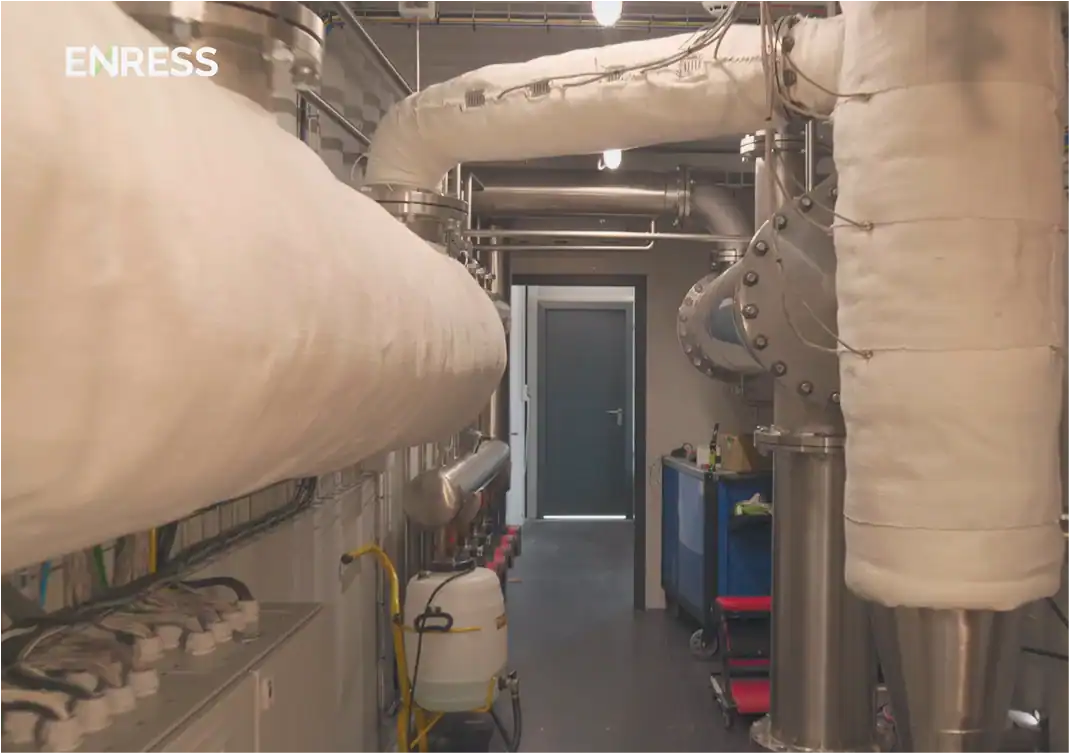

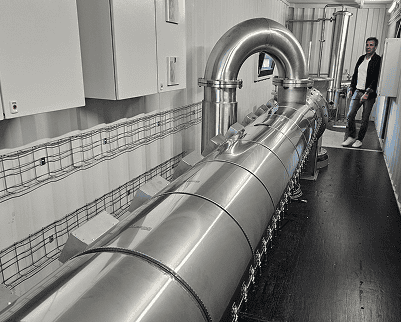

The ENRESS TDU2000® technology represents a modern solution for the treatment of waste that is not suitable for mechanical recycling. It is an emission-free, closed system using thermochemical decomposition (pyrolysis), which converts waste into process oil, gas and carbon residue.

Safe and self-sufficient operation

Our devices are designed for efficient and stable operation with maximum emphasis on safety, environmental friendliness, reliability and longevity and can be independent of a permanent connection to an external power source.

Technology & Product

ENRESS TDU2000®

An ecological alternative that aims to significantly reduce the material flows of waste that are currently going to incineration and landfill, which converts waste into new products or energy.

The technology is designed for thermochemical recycling of waste synthetic organic materials. It is safe for the environment and the operator, emission-free and in all respects as environmentally friendly as possible.

ENRESS MT_750 plastics

The plant is designed for the disposal and thermochemical recycling of plastic waste. It offers an ecologically and economically attractive method of disposal and material and energy recovery of the obtained products.

Processing up to 17 tonnes of plastic waste per day

ENRESS MT_1000 tyres

The plant is designed for the disposal and thermochemical recycling of tyres and other synthetic organic waste materials. It offers an ecologically and economically attractive method of disposal and material and energy recovery of the obtained products.

Processing up to 17 tonnes of plastic

waste per day - oils, composite plastic, tyres

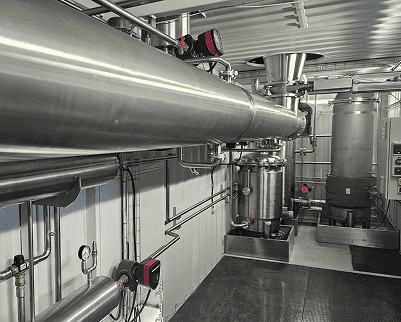

Gallery

Sustainable solutions for the industry of the future

Services in the field of thermochemical recycling of plastics

Our company specializes in advanced thermochemical recycling of plastic waste, which enables the efficient conversion of plastic back into valuable raw materials. We offer a broad portfolio of services tailored to different types of clients – from local governments to industrial companies to investors.

Why with us?

Certified REACH registered technology

Highly efficient process with low carbon footprint

Meets the requirements of European green policy

Support under grant titles and ESG frameworks

Tomorrow's technology today

Services

Tomorrow's technology today

Video

Partners and collaborating institutions: