ENRESS 750

Partners and collaborating institutions:

ENRESS 750 - plastic disposal

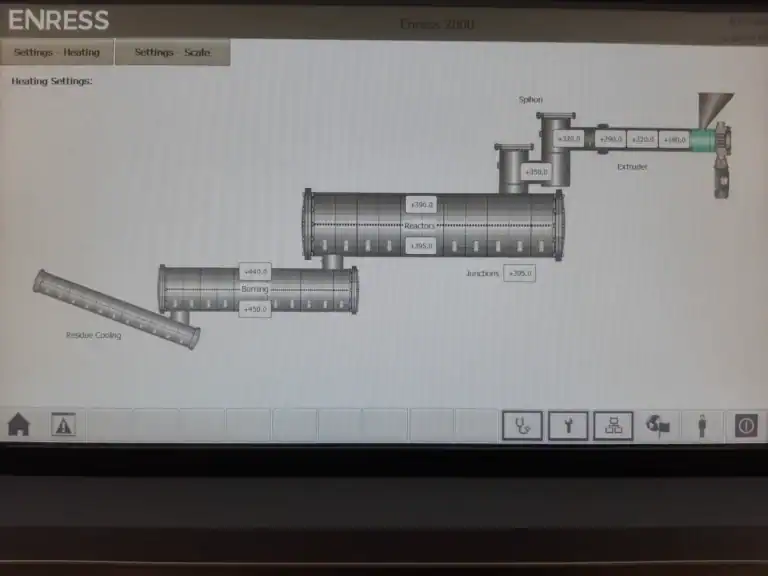

How it works

Using thermal decomposition, we can thermally decompose 700 kg/hour of plastic pulp, i.e. the annual production capacity is 5,600 tonnes/year.

With the average material balance shown, the production of the individual fractions obtained is as follows:

| A) liquid recyclate (oil) | 63 % by weight |

| B) Process gas | 34 wt. % |

| (C) inert residue | 3 wt. % |

With a plant input of 700 kg/hr, the production of new materials is as follows:

| A) liquid recyclate (oil) | 453 kg/hr (approx. 500 l/hr) |

| B) Process gas | 245 kg/hr (approx. 235 m³/hr) |

| C) inert residue – carbon | approx. 22 kg/hr. |

Use of liquid recyclate - process oil

The calorific value of the liquid recyclate is 39.31 MJ/kg. At a production rate of 453 kg/hour, the hourly energy potential is more than 17.8 GJ, i.e. almost 5 MWh.

With an available efficiency of rotating power generating machines of maximum 40%, 2 MWh can be produced at a given potential .

The liquid recyclate (oil) can be used as a saleable commodity, e.g. as a liquid thermochemical recyclate for further processing in the chemical industry or as a fuel for some types of diesel CHP units.

Use of process gas

- The calorific value of the process gas reaches 31.8 MJ/m3 and thus enables an energy production potential of 1,952 kW/hr.

- With a gas production of 235 m³/hour, the hourly energy potential is almost 7.3 GJ., i.e. more than 2 MWh.

- With the mentioned efficiency of the power generation machines, 0.8 MWh can be realistically produced from the process gas.

- The operating consumption of the technology is 380 kWh.

The by-product of electricity production, heat, can also be calculated in the energy balance. However, the amount of recoverable heat depends on the type of rotating machine used.

The use of inert carbon residue is possible in various industries.

The ENRESS 750 is supplied in a modular container solution with a size of 24.4 x 4.9 x 5.4 metres d x w x h and a total weight of approx. 24 tonnes.

The precondition for thermochemical recycling is shredded plastic waste. For the purpose of shredding, we also supply shredding equipment in cooperation with partners.

Gallery